Technical Fabrics

These textiles leverage innovative materials such as high-tenacity polyamide, technical coatings like PU or metal, and multi-layer structures. This combination delivers durable, high-performance solutions perfectly suited to specific professional uses.

Features of our technical fabrics

Each technical fabric we offer is more than just a material: it is a targeted response to a specific constraint.

These features are essential elements that guarantee performance, safety, and reliability in demanding professional environments.

Flame-retardant

Flame-retardant

Some of our fabrics are M1-certified, ensuring fire resistance according to standards.

Antistatic

Antistatic

Made from high-tenacity polyamide, our antistatic fabrics are designed to discharge static electricity effectively in sensitive environments.

Anti-abrasion

Anti-abrasion

Reinforced for areas subject to intensive friction.

Blackout

Blackout

Our blackout fabric, also M1-rated, provides an effective light barrier.

Electromagnetic shielding

Electromagnetic shielding

Our EMC fabrics are designed to effectively block electromagnetic waves.

Opaque EMC fabric

The opaque EMC fabric is a conductive material designed for electromagnetic protection applications, such as Faraday cages.

Composed of polyester, copper, and nickel fibers, it forms a double conductive layer ensuring electromagnetic sealing. Its EMC performance guarantees effective isolation against electromagnetic interference.

Its light weight and operating temperature range make it a reliable technical fabric for sensitive environments.

Weight | 80 g/m² |

|---|---|

Operating temperature | -20°C to +40°C |

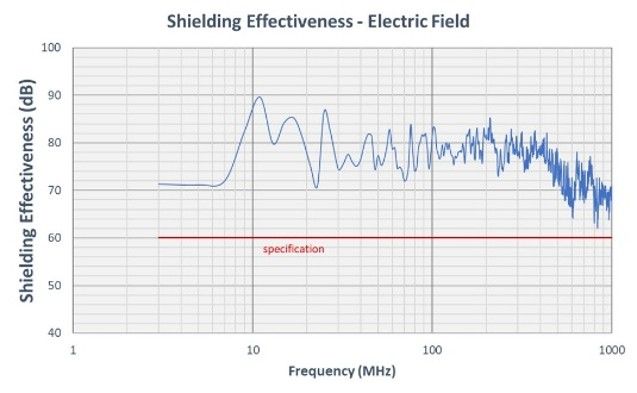

EMC performance | > 60 dB between 10 MHz and 3 GHz |

Conductivity | < 0,05 Ω/m² |

Shielding efficiency exceeds 60 dB from 1 MHz to 1 GHz.

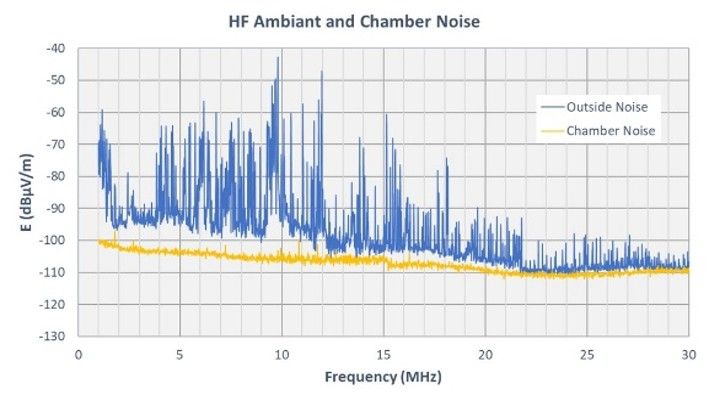

The very low noise level allows EMC measurements with extremely high radio sensitivity.

Translucent EMC fabric

Like the opaque version, the translucent EMC fabric is made of polyester, copper, and nickel.

This ultralight, translucent fabric is intended for environments requiring electromagnetic protection while allowing light transmission.

Weight | 50 g/m² |

|---|---|

Thickness | 0,07 mm |

EMC performance | > 60 dB between 10 MHz and 1,2 GHz |

Conductivity | < 0,05 Ω/m² |

Density | 240 ± 10 T |

Diamond-tip anti-abrasion fabric

The abrasion-resistant fabric with diamond tips is a robust technical material (600 denier + PU coating with diamond tips), designed to reinforce areas exposed to rubbing.

This material offers excellent resistance to abrasion and moisture.

Available in black, its woven structure and diamond-tip pattern ensure durability and stability.

Antistatic fabric

The antistatic fabric is an ultra-light, very thin technical material designed for ATEX environments.

Made of high-tenacity polyamide, it features a very fine antistatic polyurethane coating that does not accumulate static electricity.

This fabric combines abrasion resistance, antistatic properties, and durability.

Available in white, this non-harmful fabric (OEKO-TEX® Standard 100 certified) guarantees the absence of harmful substances and compatibility with skin contact.

Weight | 52 g/m² |

|---|---|

Thickness | 85 μm |

Breaking strenght | > 42,0 daN/5cm |

Elongation at break | 15 - 20 % |

Tear resistance | > 5,0 N |

Antistatic | 10⁴- 10⁶ Ω/m |

Water permeability | > 150 cm H₂O |

Blackout fabric

Classified M1 for fire resistance, this fabric is ideal for environments requiring complete blackout. Its black color provides an effective barrier against light.

This blackout fabric has a lightweight of 135 g/m², making it easy to install while ensuring efficiency.

M1 fabric (fire standard)

Manufactured in France and M1-certified, this fabric ensures fire resistance compliant with current standards, making it ideal for indoor or public applications where safety is a priority.

This PU-coated flame-retardant fabric is also designed to withstand mechanical stresses.

Available in gray or white, this fabric is waterproof and airtight, ideal for flexible and modular structures.

Weight | 150 g/m² |

|---|---|

Thickness | 180 μm |

Breaking strenght | Warp: 160 daN/5cm |

Elongation at break | Wrap: 26 % |

Tear resistance | 68 N |

Temperature resistance | -30°C to +80°C |

Abrasion resistance | 200 000 cycles under 9 kPa |

Treatment | PU flame-retardant coating 50 g/m² on one side |

The M1 fabric is also used as a structural fabric.

Contact us

Dear customers,

If you would like to contact us, please send us your request using the following contact form.

We are committed to responding to all your requests as quickly as possible and will be happy to get back to you for further discussion.

*Required fields