Material Assembly Techniques

At MICHELIN Inflatable Solutions, we cut and assemble all our materials in-house at our facilities in France (Île-de-France and Centre-Val-de-Loire).

This full control of our value chain — from design to industrialization, from cutting to sewing — guarantees quality, responsiveness, and project confidentiality.

Our integrated value chain

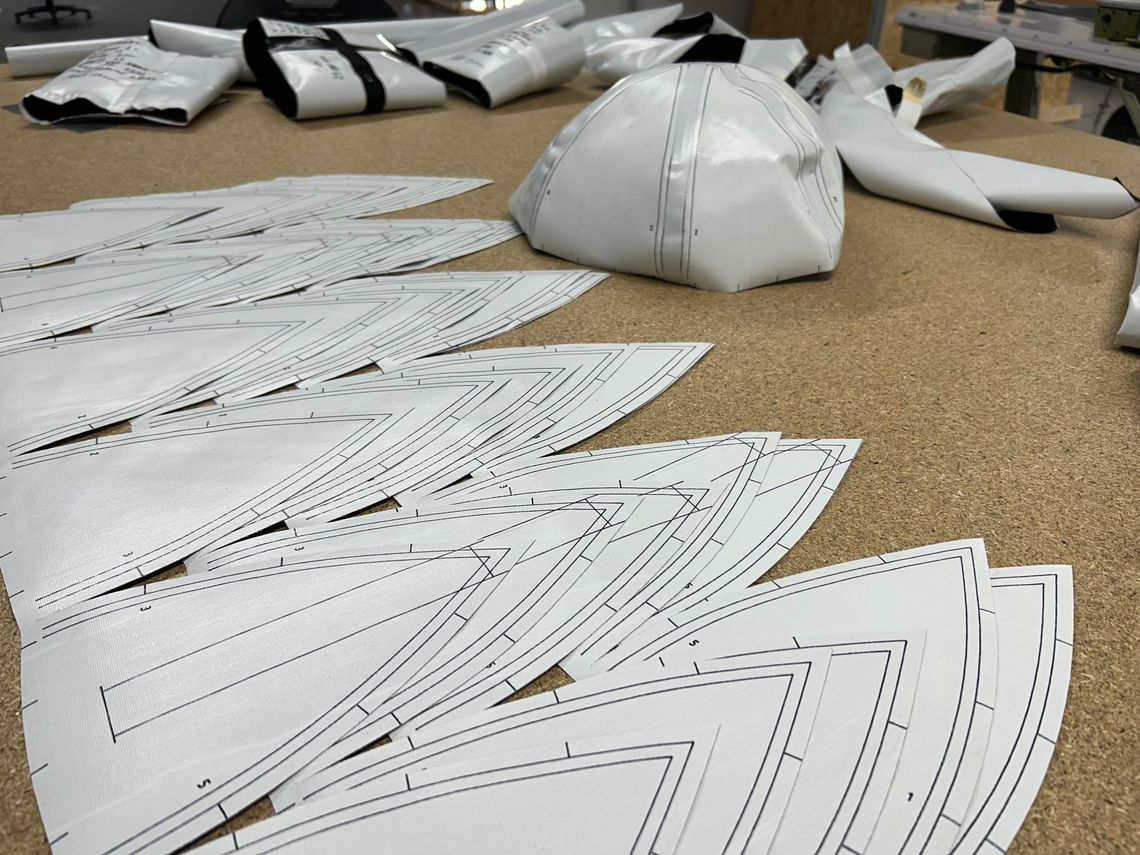

Multi-material, multi-shape cutting, all volumes

From single prototypes to large series, we cut coated textiles, technical films, and flexible composites in various formats — from small components to long lengths.Industrialization & methods

We transform your prototypes into industrializable products using robust methods: definition of process flows, tooling design, and implementation of quality controls.

This approach allows us to optimize production speed without compromising quality.

French manufacturing

All our production is carried out in our workshops in France, ensuring traceability, proximity, and operational excellence.

Our flexible textile assembly processes

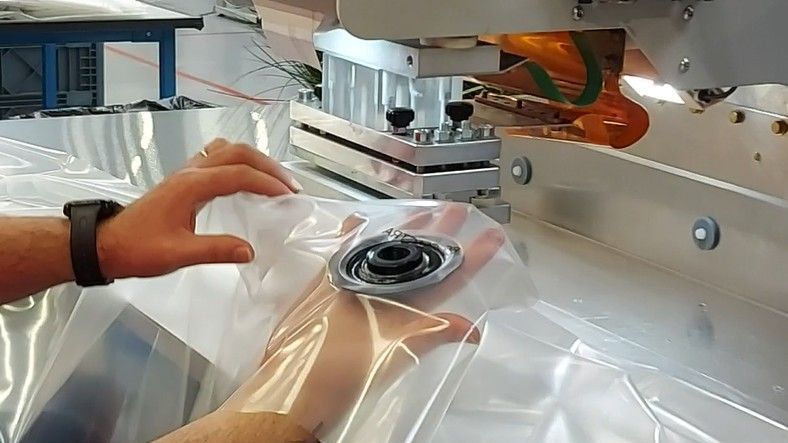

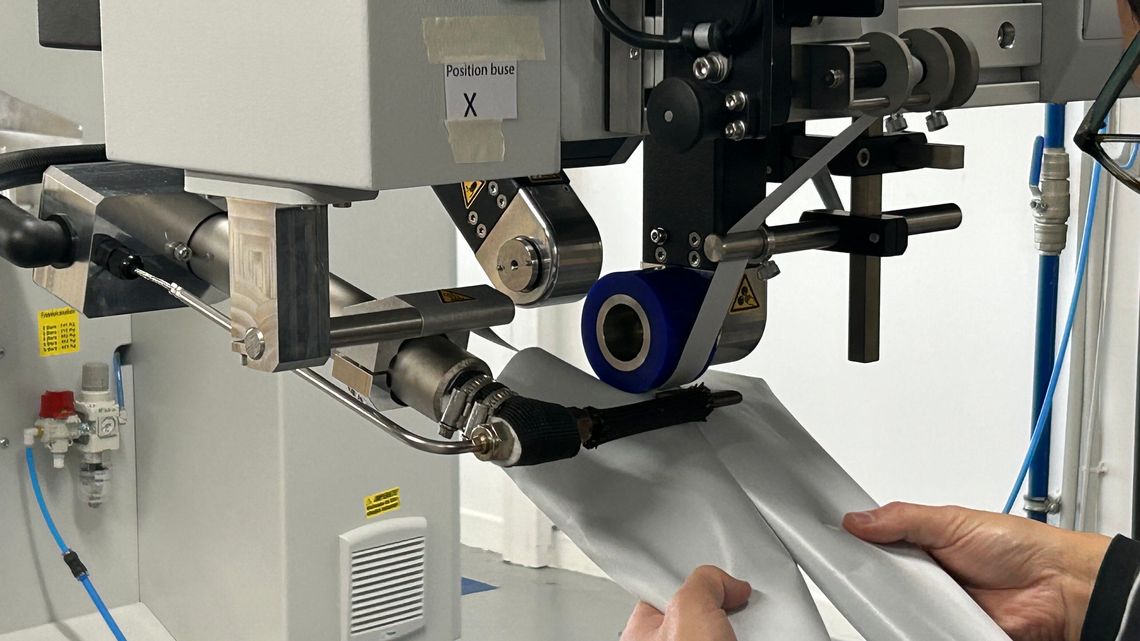

Welding

We master several complementary welding processes, adapted to thermo-weldable materials, shapes, and expected performance.

This versatility guarantees airtightness, strength, and aesthetics tailored to customer needs.

Why multiple techniques ?

Because each material × shape × use combination is unique, our multi-process approach allows us to find the best balance between quality, cost, lead time, and performance.

Our welding types

High-frequency welding

(dielectric heating)

Thermal impulse welding

Hot air welding

Our welding variants

By imprint for precise weld paths.

By die-cutting to cut and weld in one step.

Short and long lengths for both complex details and XXL assemblies.

Resistance sizing

We adjust imprint, overlap, energy/pressure, and feed speed to achieve the target resistance or airtightness level. Each configuration is validated by standardized tests (tensile, peel, leak control).

Finished welded products

Our welded assemblies are not just components: we deliver finished products, ready for use and compliant with your requirements.

Each product is tested and validated according to your criteria (airtightness, strength, aesthetics) for immediate integration into your solution.

Do you have a welding project ?

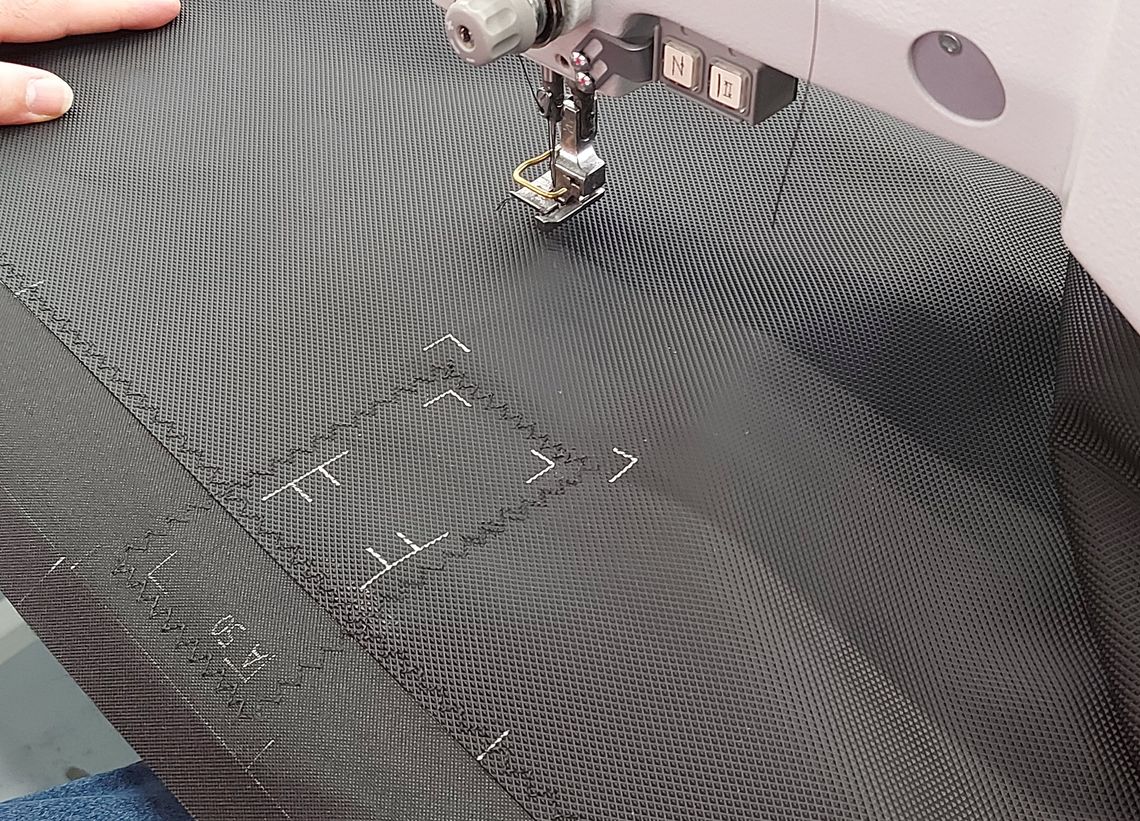

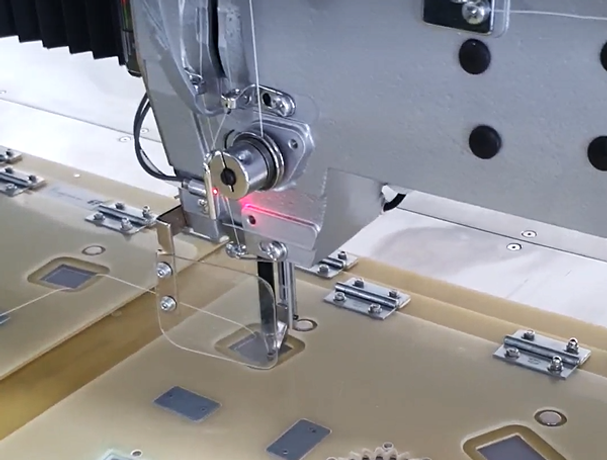

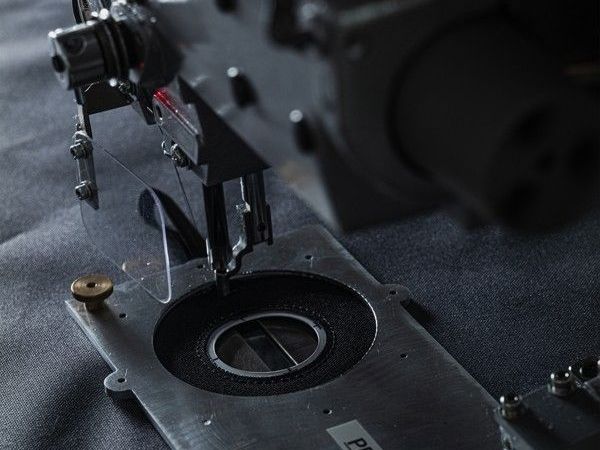

Sewing

Inspired by fashion, leather goods, sailmaking, and saddlery, our sewing brings flexibility, repairability, and premium finishes.

We adapt our techniques, machines, and accessories to the performance expected by our customers (strength, airtightness, UV resistance, etc.).

Fully sewn in our workshops, we manufacture 100% assembled products using this method, such as covers, doors, and bags with robust and aesthetic finishes.