Aeronautics & Space: Faraday cage and custom-made products

The aeronautics field is currently facing real challenges. Michelin Inflatable Solutions is acting to solve the major problems by overturning the processes of the main businesses in the sector.

Thanks to our customers’ trust, we are designing innovative alternatives for all companies in the aeronautics field.

Through inflatable solutions equipped with technical materials, our customers have obtained critical gains in terms of logistics, weight, and compliance with schedules, which also allows for filing patents and for the industrial validation of concepts.

reconsider the use of measurement equipment

Validated by the authorities, they allow for homologating devices, and for protecting sensitive equipment and staff from electromagnetic waves. Our solutions also provide opportunities for a different way of performing maintenance on all aeronautical equipment.

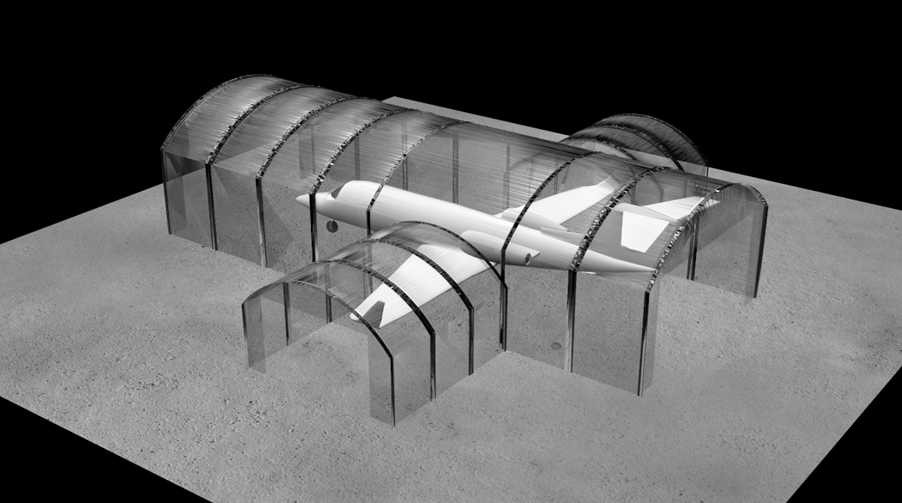

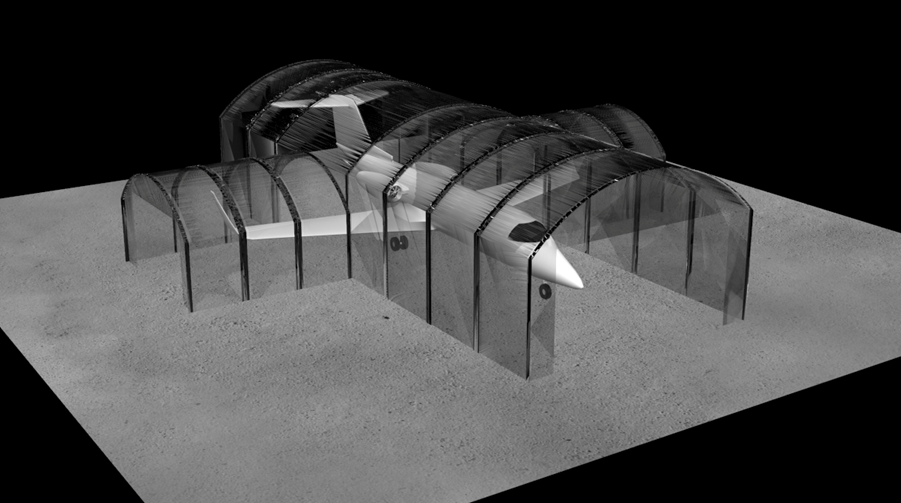

Perfect for ephemeral requirements, our inflatable solutions allow, for example, for performing electromagnetic tests on simple, complex, heavy, or bulky assemblies such as an aircraft, in our large Faraday cage and lightning tests with isolators in the form of a string of cones (lightning test coaxial line).

The time needed to set up our inflatable solutions is exceptionally short: about ten minutes to install a shelter of around 25m² to under a day for one measuring 900m² (F6X shelter).

In short, Michelin Inflatable Solutions replace existing alternatives in order to increase gains in productivity, shorten schedules and reduce storage requirements.

OUR solutions

All our solutions are designed and developed for our customers’ specific requirements. They adapt to their products and their environments. As our products can be deployed quickly and anywhere, it is a real plus for handling, transport, and use; the solution comes from the product and not the other way round. This is a real advantage for the environment and especially for CO2 emissions.

OUR Services

Our after-sales service based in the Paris region is available to answer your questions and provide you with the best possible support.